Get a Quote For Your Project

Expert Advice and Investigations

When undesirable incidents take place leading to loss of lives, injuries to personnel, near-misses, environmental impact, loss of production or additional rectification costs, having an independent expert working on your team will ensure that the root cause and all contributory factors are successfully identified.

Ascribe Engineering provides expert, independent and professional engineering advice on mechanical and structural matters.

Root Cause Failure

- Cause & effect analyses

- Failure modes and scenario assessments

- Development of inspection strategies

- Development of inspection response strategies

Insurance Loss Adjustment

- Failure of mechanical plant, equipment and structures

- Water and fire damage to plant and equipment

- Failures of drives such as gearbox failures and motor burnouts

- Premature failures due to overloads and fatigue

Expert Witness

- Engineering expert advice to legal fraternity

- Accident investigations

- Assessment of Workplace Health, Safety and Environmental incidents

- Independent audits, reviews and mediation

Assessment by Field Measurements

Ascribe Engineering provides a comprehensive suite of test, measurement and field data analysis services using industry standard signal conditioners, data loggers and software as well as bespoke equipment and software. Some of the key areas of expertise include, multi-channel data loggers for short term, long term or remote data acquisition, telemetry instrumentation for measurements on shafts (torque telemetry) or mobile equipment, multi-channel high speed radio transmitters.

Tests, Assessments on Machinery & Structures

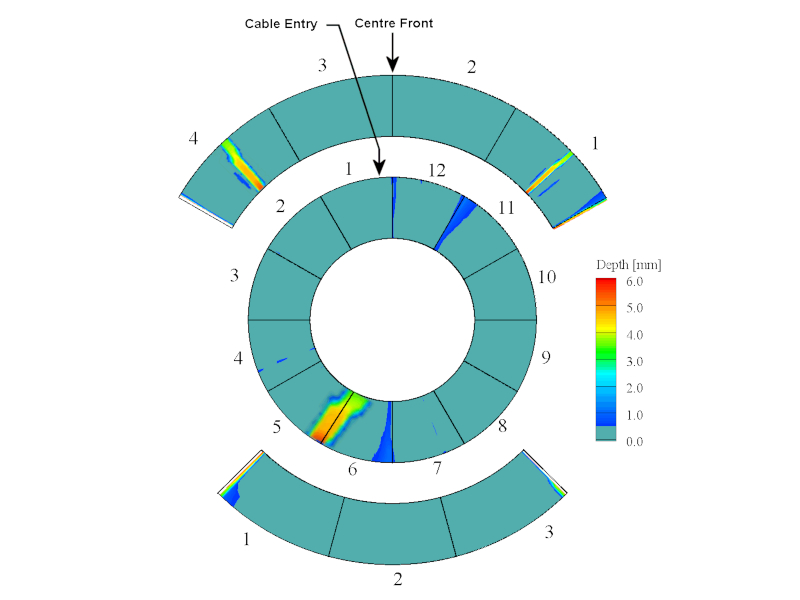

- Slew bearing assessments (draglines, shovels, stackers/reclaimers, shiploaders)

- Centre of gravity assessments (draglines, shovels, stackers/reclaimers, shiploaders)

- Commissioning tests on machinery and structures

- Structural load and life assessments

- Vibration and modal assessments of structures

Tests and Assessments on Rollingstock

- Ride index and quality (passenger and driver comfort)

- Hand/Body vibration

- Structural modes

- Bogie stability and hunting performance

- Bogies life assessments

Specialist Services

- Roller load assessment

- Spall inspections

- Centre of gravity assessments

- Suspended load assessments

Design, Design Audit, Design Upgrade & Specifications

Depending on project needs, Ascribe Engineering would utilise Australian and International codes and guidelines and a range of tools from first principle design assessment (hand calculations), Computer Aided Design and Finite Element analysis techniques.

Inclusive of these capabilities is the cross-development of loads and load cases. At Ascribe Engineering, we recommend the verification of loads and analyses via field tests and measurements wherever necessary.

Finite Element Analysis

- Linear and non-linear, static & dynamic

- Contact analysis, including bolt pretension

- Heat transfer

- Buckling

- Modal analysis and forced response

- Fatigue and damage index

Computational Fluid Dynamics

- Steady state and transient flows

- Forced and natural convection

- Couple structural and fluid simulation

- Mixed flow

Drafting

- 2D and 3D parametric

- Engineering and fabrication drawings

- FEA and CFD model development

Due Diligence and Integrity Assessment

Ascribe Engineering can provide due diligence and integrity inspection advice on structures and mechanical plant and equipment. Such assessments are typically undertaken as part of identifying condition after incidents, ongoing maintenance needs or during procurement stages of used structures and mechanical plant and equipment.

As part of this advice, Ascribe Engineering can provide condition assessment reports, repair/upgrade advice and work scopes for carrying out the work.

Typical Plant and Equipment Assessed

- Processing and wash plants

- Yard machinery

- Mechanical plant and equipment

- Industrial Buildings

- Bulk handling equipment

Condition Monitoring and Strategy

- Slew bearing axial drop and remnant life

- Slew rail wear, spalling and remnant life

- Structural cracking and repair strategy

- Monitoring of safety devices and guarding

Structural and Mechanical Plant Risk Assessment

- Identification of hazards

- Evaluation of risks and setting risk-based priorities

- Design safety assessments (SiD, FMECA & HAZOP)

Selected Projects

Contact Us

8/83 Leichhardt St, Spring Hill, QLD, 4000

![]()