Slew Bearing Upgrade

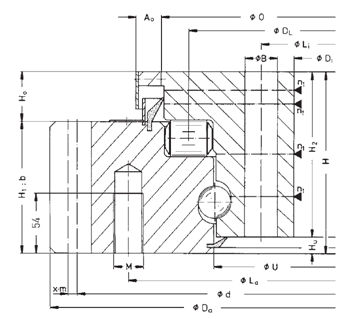

In preparation for a machine upgrade, Ascribe Engineering was commissioned to provide expert assistance with the procurement of an upgraded large diameter slew bearing and the support of the machine.

- Date: 2019

- Client: Undisclosed

- Project Type: Bulk materials handling

About this Project

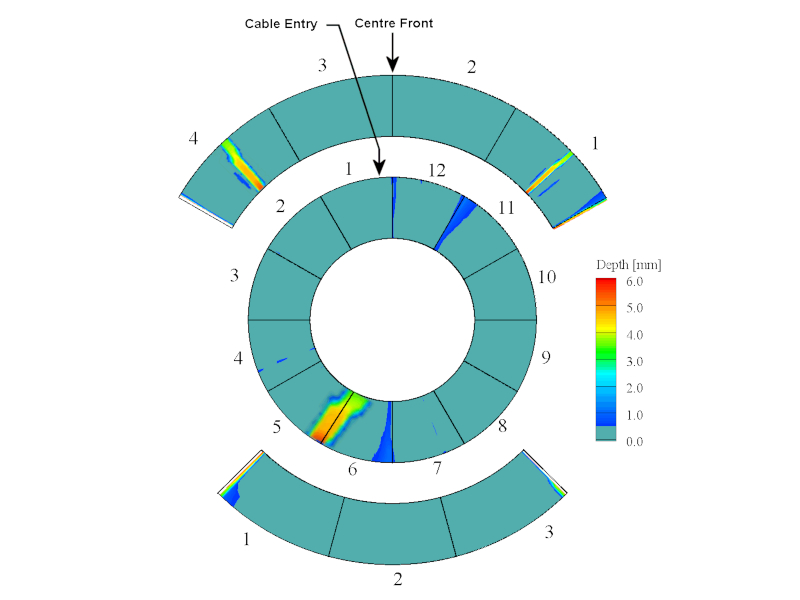

In this instance, the bearing pads had also been incorrectly machined whilst the superstructure was supported under three external jacks. This has likely led to an increase in the peak roller load, resulting in a reduced life.

Ascribe Engineering offered engineering assistance to re-profile the bearing pads whilst the superstructure was evenly supported.

- Provision of a detailed technical purchase specification

- Onsite inspection of existing slew bearing and jacking arrangement

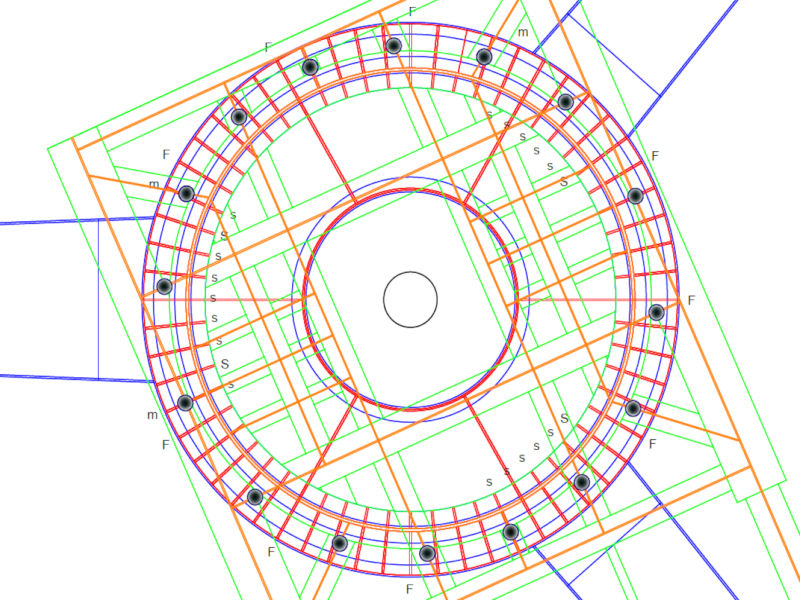

- Engineering layout and preliminary concept design for multi-jack uniform support arrangement

The Australian design code for bulk handling equipment AS4324 part 1 provides little guidance to the designer for the selection of mechanical items such as large precision slew bearings.

Ascribe Engineering can provide expert advice in relation to slew bearings including:

- Calculation of design loads

- Selection of roughness factor

- Upgrades of existing slew bearings

- Calculation of B10 bearing life

- Calculation of slew hold down bolt capacity

- Procurement specifications

- Audit of slew bearing selection and design

- Engineering of machine support during slew bearing replacement

- Failure investigation

Contact Us

8/83 Leichhardt St, Spring Hill, QLD, 4000

![]()