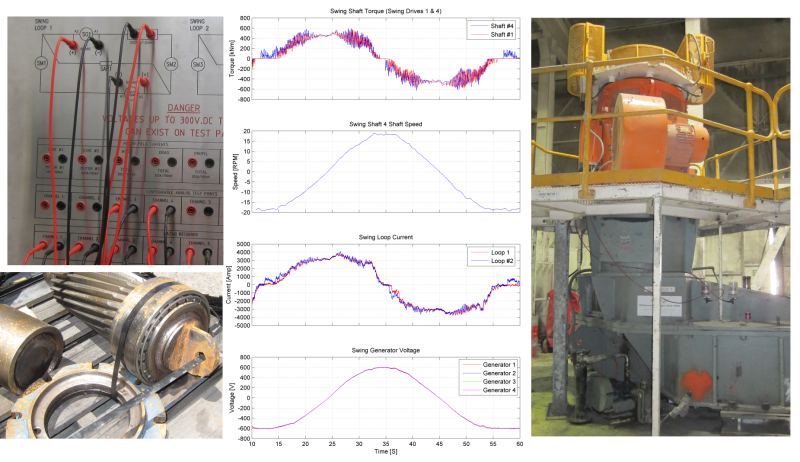

Shaft Torque Measurements

Ascribe Engineering personnel have extensive experience in identifying drive train problems in machinery.

In the wake of a failed input shaft on a dragline swing drive system, Ascribe Engineering was commissioned by one of their mining clients to quantify the swing drive loading and the presence of any torsional oscillations.

With the aid of the measurements and the ensuing investigation, Ascribe Engineering was able to identify the cause for the failure.

- Date: 2019

- Client: Undisclosed

- Project Type: Test and Measurement

About this Project

Ascribe Engineering utilised its failure investigation and test and measurements skills to assess the possible causes for the failure and investigate the nature of shaft loading.

Shaft torque telemetry system and an encoder were used to obtain the torsional stresses from two rotating shafts and the speeds.

Although it was established that there are significant torsional oscillations and recommendations to fit cross-loop resistors were made, the misalignment of the shaft was identified as the leading cause for the failure.

Services included:

- Measurements of cross-loop voltages, torsional stresses and shaft speeds

- Identification and analysis of torsional oscillations

- Engineering calculations regarding the impact to shaft, bearing and gearing lives

- Advice on the elimination of torsional oscillations for long component lives

- Assessment of the effects of the coupling misalignment.

Torsional oscillations arise from the rotational mass of the motor armature torsionally oscillating primarily against the stiffness of the drive train all the way to the final drive pinion. Electro-mechanical effects do also contribute to sustain the torsional oscillations.

This electro-mechanical system has its own natural frequency, which in the case of draglines is usually fairly low because of the long swing shaft length and high gear ratios.

The low natural frequency often falls within the range in which excitation of the final drive pinion tooth mesh frequency can occur.

It is not uncommon for torsional oscillations to increase peak torques of the order of 40% or more. Such increases can have a significant effect on life due to the inverse power relationship of load and life on shafts and gearing.

Contact Us

8/83 Leichhardt St, Spring Hill, QLD, 4000

![]()