Dragline Stability and Centre of Gravity

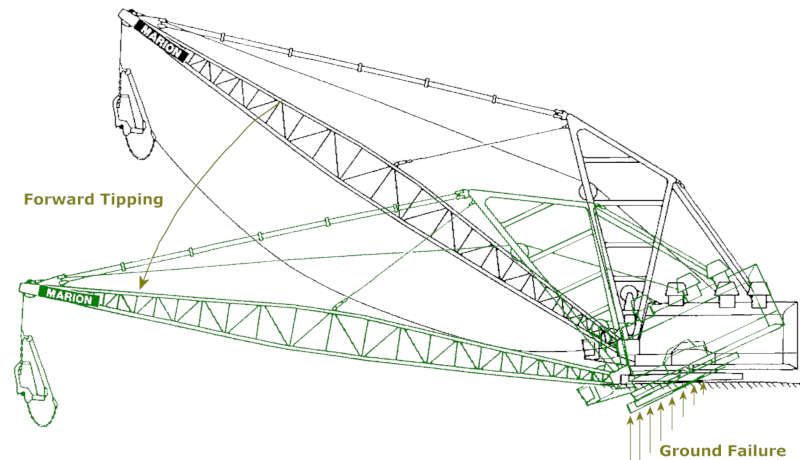

Earlier in the year, Ascribe Engineering provided expert assistance to an international coal producer where one of their draglines had a forward tipping incident in which the ground support under the tub failed.

In the wake of this incident, Ascribe Engineering was commissioned to investigate the possible imbalance of the machine and what can be done to rectify the situation.

- Date: 2019

- Client: Undisclosed

- Project Type: Draglines

About this Project

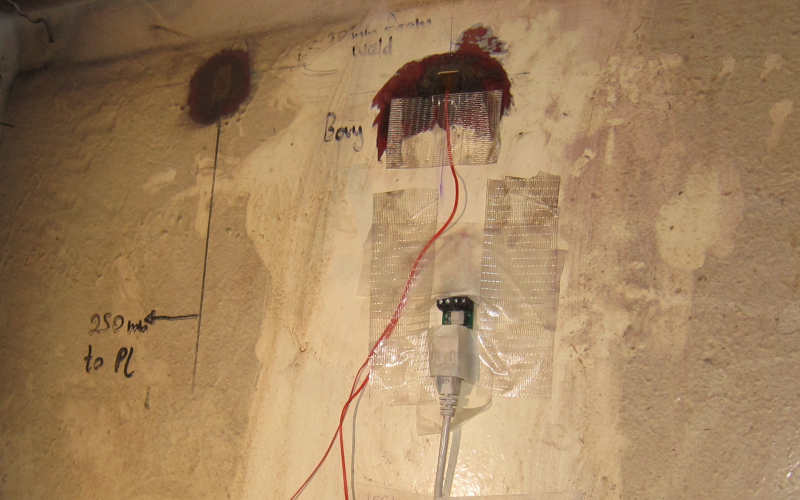

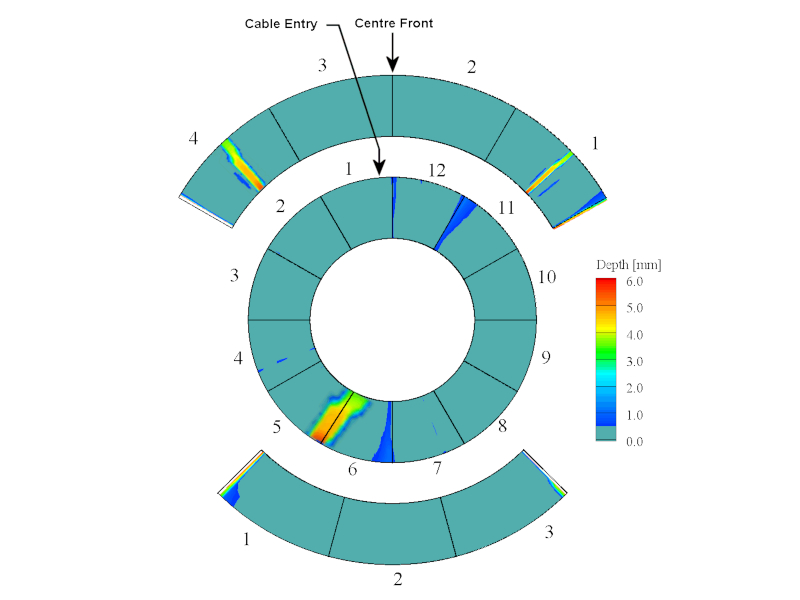

Ascribe Engineering installed multiple gauges within the machine to determine the centre of gravity position. The centre of gravity of the revolving frame was measured, along with the total mass of the rotating portion.

In this instance, the machine was found to be forward heavy than typically expected. Additional ballast was added and operating guidelines for dragline bench preparation were reviewed.

- Measurement of actual centre of gravity position

- Engineering advice with regards to propelling on inclined slopes

- Engineering advice regarding ballasting

Some indications of improper machine balance may manifest themselves as tub hook shoes touching the rail during digging, roller circle opening up during propelling or difficulty in the machine walking and subsidence of the dragline pad.

Ascribe Engineering can provide expert advice in relation to machine mass and centre of gravity including:

- Calculation and actual measurement of centre of gravity

- Changes to centre of gravity position with mass additions or subtractions

- Advice on impact to dragline propel with centre of gravity changes

- Advice on total suspended load and rated suspended load upgrades

- Advice on bucket positioning during walking

- Advice on ground preparation and tub lip pressures

- Audit of dragline upgrades and modifications

- Engineering support during shutdowns

Contact Us

8/83 Leichhardt St, Spring Hill, QLD, 4000

![]()