Due Diligence and Integrity Assessment

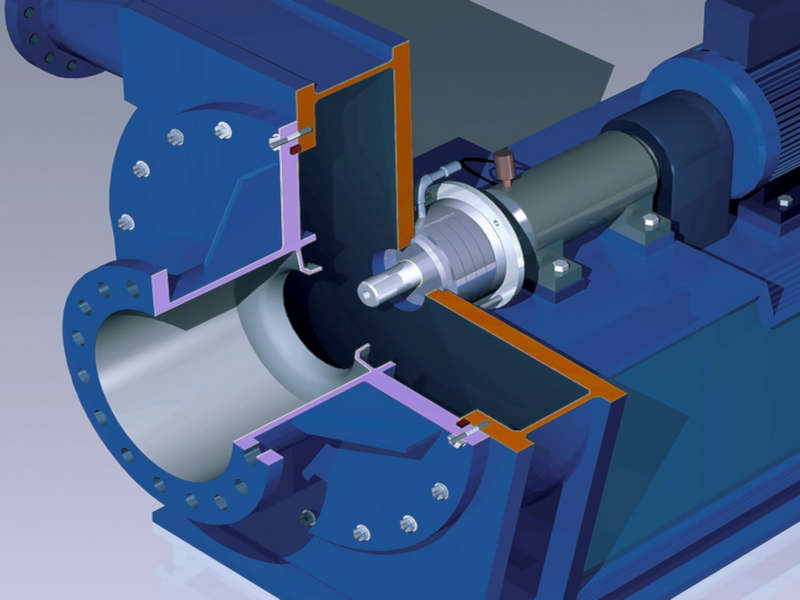

Ascribe Engineering provides a comprehensive range of mechanical due diligence and integrity inspections, machinery condition assessments, repair/upgrade advice and work scoping services.

We utilise Health, Safety and Environmental risk-based as well as commercial risk-based condition integrity approach following Australian and International Standards.

Due Diligence and Integrity Assessment

Mechanical and machine inspections, condition assessments, preventative maintenance, access and guarding audits.

Visit our projects area to see examples of how we can add value to the management of your assets.

Risk Based Approach

Ascribe Engineering follow a risk based inspection process where findings are identified and assessed according to their level of risk. Structural integrity risks generally relate to:

- Corrosion (due to environmental factors and surface protection)

- Fatigue (due to loading spectrum and the accumulation of loading cycles over time)

- Collisions or impact damage

- Inadequate design (e.g. an overloading event never considered by the designer)

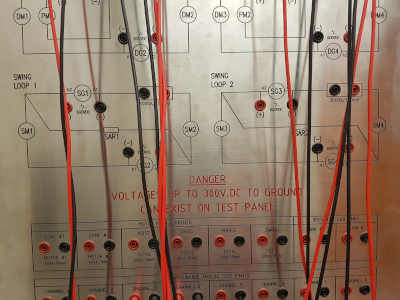

- Mechanical, structural and electrical inspections

- Condition monitoring

- Asset management plans and audits.

- Residual life analysis.

- Repair work scope definitions.

- System audits of asset management system

Machine Integrity Inspections

Detection of cracking (via both visual, ultrasonic and magnetic particle testing) is therefore an important aspect of any inspection strategy.

An inspection strategy defines critical areas for inspection and inspection frequency. Determination of the critical areas for inspection are typically be based on the following:

- Experience on various equipment and main loadpath

- The stress levels determined either via strain gauge measurements or analysis

- The design details of the structure or machine

- Any history of past failures

- The redundancy of the member or component in question

Call For a Quote:

+61 429 883 183

Having a Response Strategy

Asset managers are generally familiar with procuring inspections.

However, often a report is provided from an inspection service supplier that simply contains inspection findings with little guidance as to the management of the finding or its implications.

For example, an inspection finding may highlight a 20 mm long transverse crack in a chord member. But without a rigorous inspection response strategy, the usefulness of the knowledge that there is a crack is diminished.

- What length of crack is acceptable before it must be repaired prior to becoming critical and leading to fast fracture?

- What is an acceptable growth rate for the crack before it must be repaired?

Contact Ascribe Engineering to learn more and develop an inspection response strategy for your asset.

Email us for a Quote or use the Online Contact Form

Inspection Response Strategies

- minimise unscheduled downtime

- maintain structural integrity

This is achieved by:

- consideration of crack growth rates and inspection frequency

- criticality of the member or component in question

- allowable defect size at a particular location

An inspection response strategy is generally composed of response categories of increasing urgency and action. The highest category of defects would invoke an immediate stop of machine operation, whilst the lowest category would be to continue to monitor defect.

Ascribe Engineering recommend that the inspection response strategy should be reviewed and updated every 5 years.

Related Services

Contact Us

8/83 Leichhardt St, Spring Hill, QLD, 4000

![]()