Assessment by Field Measurements

We routinely undertake field measurement based assessments on draglines, shovels, mobile bulk handling machines, boom structures, rollingstock (passenger and freight rail equipment and trams) conveyors, vibrating screens and mills.

Assessment by Field Measurements

Visit our projects area to see examples of how we utilise our test and measurement skills.

Digital Data

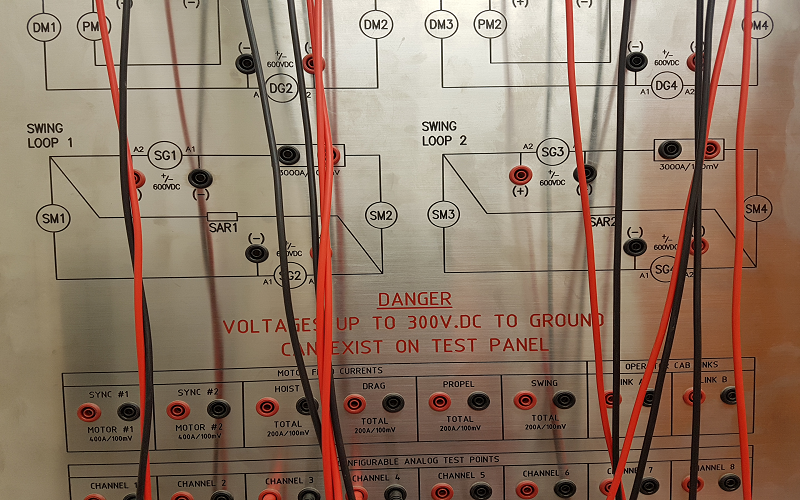

Strain, direct stress, acceleration, temperature, GPS and video are just some of the quantities routinely recorded by Ascribe Engineering.

Apart from our industry standard data loggers and signal conditioners, Ascribe Engineering have a number of purpose built test modules available.

Multi-channel high speed radio transmitters for strain or acceleration measurement.

Strain Gauging

- Steel and stainless steel

- Aluminium

- Concrete

- Plastics and polyethylene

- Fiberglass

Twist tests on rail vehicles and compliance testing of bogies.

Bridge and machine structural health monitoring.

Verification of finite element analysis.

Temperature compensation and installation in cold weather environments.

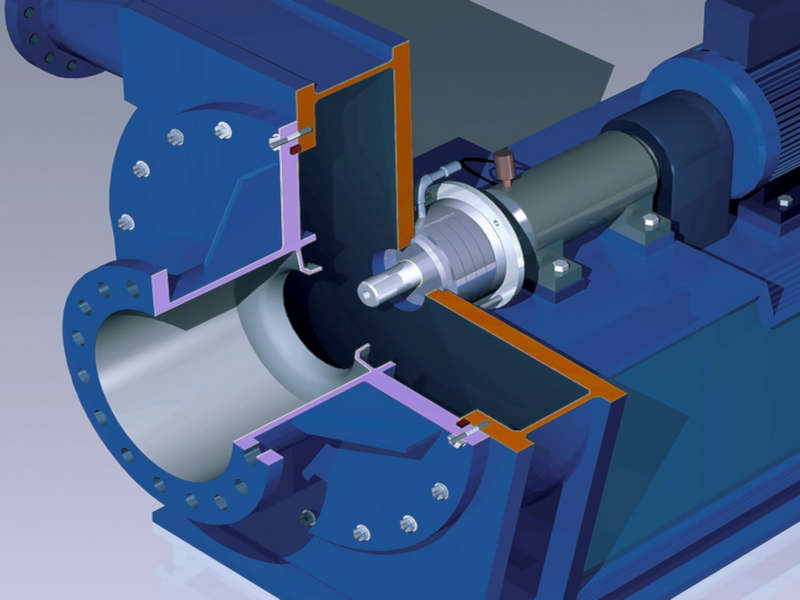

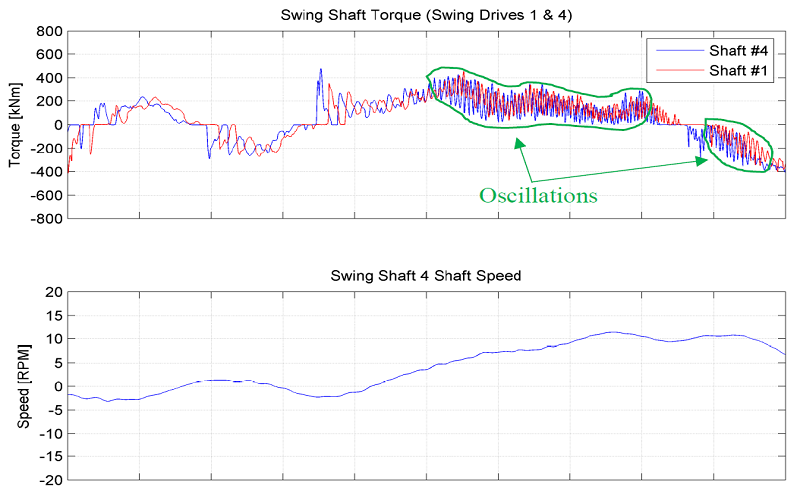

Specialist torque testing on shafts and rotating structures using radio telemetry instrumentation.

Full, half and quarter bridge configurations.

Email us for a Quote or use the Online Contact Form

Value of Data

Ascribe Engineering offer peace of mind when executing your test and measurement needs. We treat each measurement activity with attention it deserves.

We pride ourselves on attention to detail, record keeping, data capture and the protection of your test data throughout the measurement campaign.

- Life prediction and life extensions

- Maintenance scheduling based on data

- Inspection response strategies

- Real time data visualisation

Email us for a Quote or use the Online Contact Form

Vibration

- Railcars and bogies

- Vibrating screens

- Pumping stations

- Mills

- Drive motor structures

- Reclaimers and shiploaders

- Washplants

- Mining, oil and gas structures

Measurements of operating vibration levels are usually key to understanding the structural dynamics for troubleshooting, root cause investigation and failure analysis. Ascribe Engineering routinely undertake vibration measurements to determine operating deflections, natural frequencies and the mode shapes. Our hardware tools include:

- Simultaneous multi-channel high speed data acquisition instrumentation

- Long term or short duration data loggers

- High speed radio transmitters

- High and Low g-force accelerometers

- LVDT probes, string-pots, lasers

Specialist Dragline Services

Roller Load Assessment

Strain gauges on the main roller circle supporting diaphragms and a specialised instrumented pin installed within the roller circle are used to obtain the roller circle loading. The pin measures the actual crush loads seen by the highest loaded roller as the machine slews.

By carrying out a roller load test, rail installation errors, roller size differences and roller mis-tracking can be identified and corrected to maximise the life of the roller circle.

The roller load test is a highly complex test and requires significant experience not only to perform the test but to interpret the measured results. Ascribe Engineering personnel have decades of experience in assessing roller circles and slew bearings on the various slewing machinery.

.

Centre of Gravity Assessment

Knowledge of the actual as-measured Centre of Gravity position is critical when carrying out structural/mechanical upgrades, increasing the target suspended load, assessing stability during propelling, machine support during various maintenance shutdowns and assessing operating pad capacity/stability.

Centre of gravity assessments are typically conducted by using strain gauges, load indicating shims or loadcells.

Roller Circle Spall Inspection

A custom built scanner is installed within the roller circle which scans the surfaces of the rails for spalling and other damage.

On most draglines, the test takes approximately 2 to 3 hours to complete. Typically, areas of significant spalling are identified during the test and highlighted to maintenance staff for attention with remedial measures recommended.

In addition to rail scanning, Ascribe Engineering also conducts visual inspection of slew bearings and roller circles including the wrapper bands, rollers, hook rail and shoes. Based on the results of the spall test and inspection, professional engineering advice on the current levels of risk in continued operation and what can be done to increase reliability are provided.

Suspended Load Assessment

Many draglines today have on-board payload monitors; however, experience suggests that unless properly calibrated, actual payload values may differ substantially from those predicted by the monitors. The discrepancy for the most part stems from the use of hoist and drag motor operating electrical parameters to estimate the rope pull and the payload. Further, the electrical parameter based payload measurements are inherently inaccurate and overlooks rope dynamics.

Ascribe Engineering can undertake a suspended load test in which instrumented pins are installed in the bucket rigging. A telemetry system is used to relay the measured payload to a base station over a period of normal operation. The measured payload values at the rigging can be compared to those measured by the on-board payload system to obtain a calibration.

Dragline Ventilation and Dust Assessment

Ascribe Engineering undertakes air flow testing to establish the effectiveness of dragline ventilation systems as well as troubleshooting existing ventilation issues. Our engineering assessments can consider both overheating problems and dust ingress and are conducted by experienced RPEQ qualified engineers.

Ascribe Engineering also utilises Computational Fluid Dynamics assessments to model air flows, heating and cooling rates and dust flow paths when necessary. This is particularly relevant if any upgrades to the ventilation system are to be considered.

Specialist Rail Services

Our Rail Capability

Ascribe Engineering personnel have a long history of providing engineering services to the rail industry including passenger rail, cargo and bulk rail transport, trams and light rail. The services offered range from design, design assessment, failure assessment and type testing.

When it comes to rail related test and measurement projects, depending on the project needs, Ascribe Engineering can utilise a range of sensors including:

- Simultaneous multi-channel high speed data acquisition instrumentation

- Long term or short duration data loggers

- High speed radio transmitters

- Video and GPS

- Strain gauges

- High and Low g-force accelerometers

- LVDT probes, string-pots, lasers

Instrumentation and Testing

Our preferred supplier of test and measurement equipment is HBM. We own a range of the latest HBM software and hardware platforms. Our standard test and measurement capabilities include:

- Multichannel static and dynamic strain gauging

- Assessment of structural and free-body modes

- Ride index and quality (passenger and driver comfort)

- Hand/Body vibration

- Bogie stability and hunting performance

- Bogie life assessments

- Bogie twist tests

- Bearing and gearing assessments

Related Services

Due Diligence and Integrity Assessment

Contact Us

8/83 Leichhardt St, Spring Hill, QLD, 4000

![]()